If you wish place an inquiry, please fill in the

If you need help filling in the form, please contact us at info(at)burckhardt.com

You can download our actual leaflets as printable PDF Files

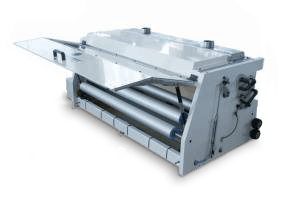

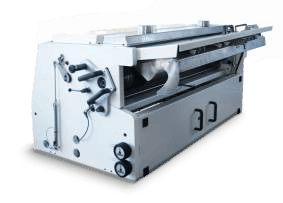

A completely new development based on customer’s and user’s inputs!

Hot: 400°C

Speed: 300m/min

The new construction optimzes high temperature, high speed

and fastest exchange of perforating tools.

| Machine Type | Hot Pin Perforating Unit |

|---|---|

| Machine Name | PAB-HS |

| Working width | Up to 2’000 mm |

| Perforating roller | Core Ø 110 mm Perforating segments according to customer’s specification Ø over pin tips: 130 – 200 mm |

| Counter Roller | Roller Ø 140 – 160 mm Tampico fibre brush Option: (according to application) Rubber |

| Heating system | “Hot Oven” construction Combination of external high-performance ceramic heating and internal electrical heating Combined Heating power: up to 13kW per meter width |

| Working temperature | up to 400°C (measured at perforating ring) |

| Drive system | 2.2 kW, DC-motor, 50Hz, 400 V |

| Line Speed | Up to 300 m/min |

| Penetration adjustment | Manual control with penetration indicator |

| Electronic control | Cabinet with push buttons, temperature display and adjustment, line integration via 0-10 V signal Option: Cabinet with Siemens touch-panel TP 177, control/display of all mechanical functions and parameters as speed and temperature, line integration through 0-10 V signal, manual synchronization adjustment, adaption of line speed and perforation speed at control panel, modem connection for remote maintenance |

| Energy supply / consumption | 50Hz, 400 V, Energy consumption 13 kWh per meter working width |

| External dimensions | Total length = working width + 800 mm Height: 700 mm (approx.) Depth: 700-1000 mm (approx.) |

| Options | Segmented pinning for special perforating pattern Dedicated construction for fast roller change Dedicated construction for fast pin ring exchange |

Notifications